I have been impressed by this creator for many years. I have also been helped out of a few technical and creative jams by Tony Hansen. For those working in ceramics, Digitalfire is an amazing resource. This is a shout out to all of the amazing work that Tony Hansen does for the ceramics community!

This is an article from Tony’s Blog, which caught my attention because I am always wondering what the consumer applications for 3D printers are:

Context: 3D Printing Ceramics

Saturday 24th February 2018 , By Tony Hansen

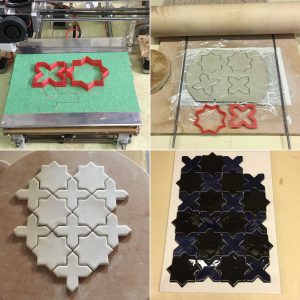

Making ceramic tile shapes by 3D printing your own cookie cutters

This was done on an affordable RepRap printer. The red plastic templates were drawn in Illustrator, extruded in Fusion 360 and sliced and printed using Simplify3D (which took about 30 minutes each). The round wooden block was used to press these cookie-cutters into the clay. The plastic wrap made sticking a non issue (and rounds the corners nicely). The clay is a low fire, buff burning talc body (Plainsman L212). Commercial bottled glazes were applied by brushing (in three coats) after bisque. The tiles were fired at cone 03. This is an old classic design that I discovered when researching Damascus tile. The toughest obstacle was learning how to use Fusion 360. It turns out that cookie cutters are a starter project for many 3D software packages, there are lots of videos on making them.

Context: 3D Printing Ceramics

Saturday 24th February 2018